Visual Process Intelligence

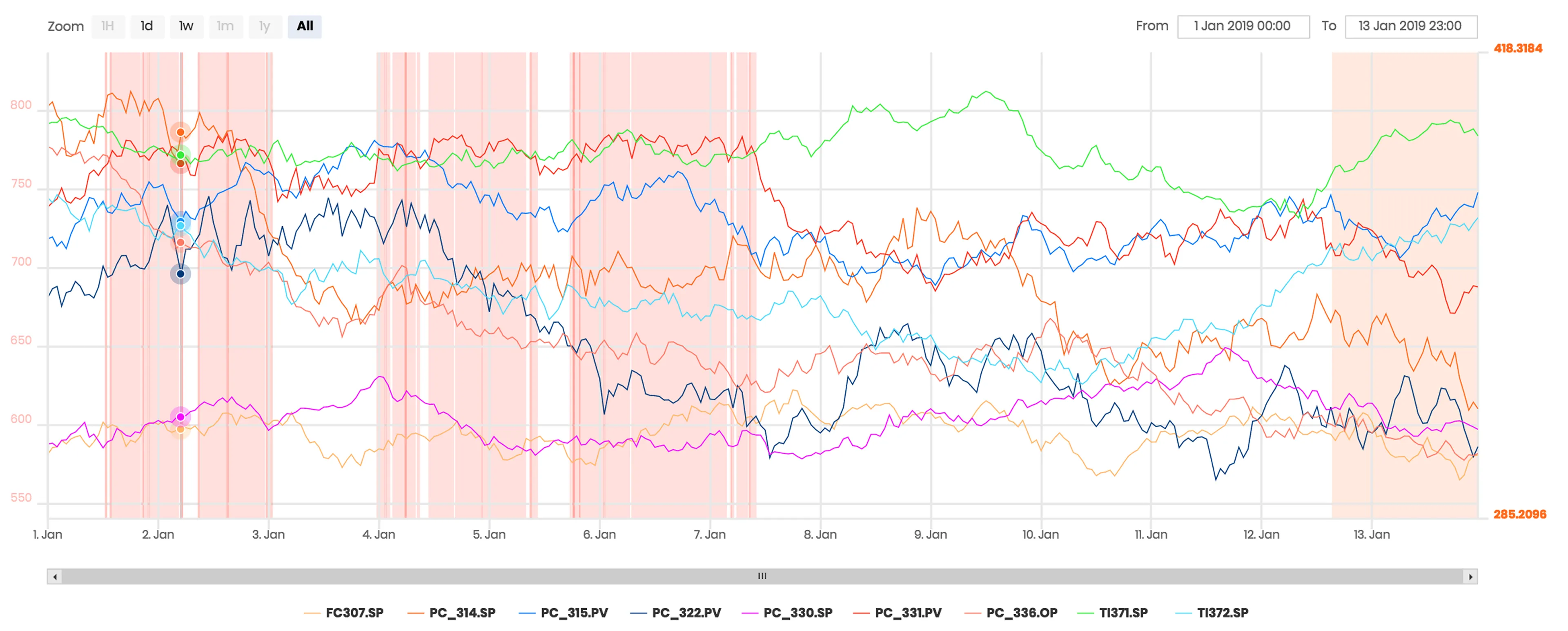

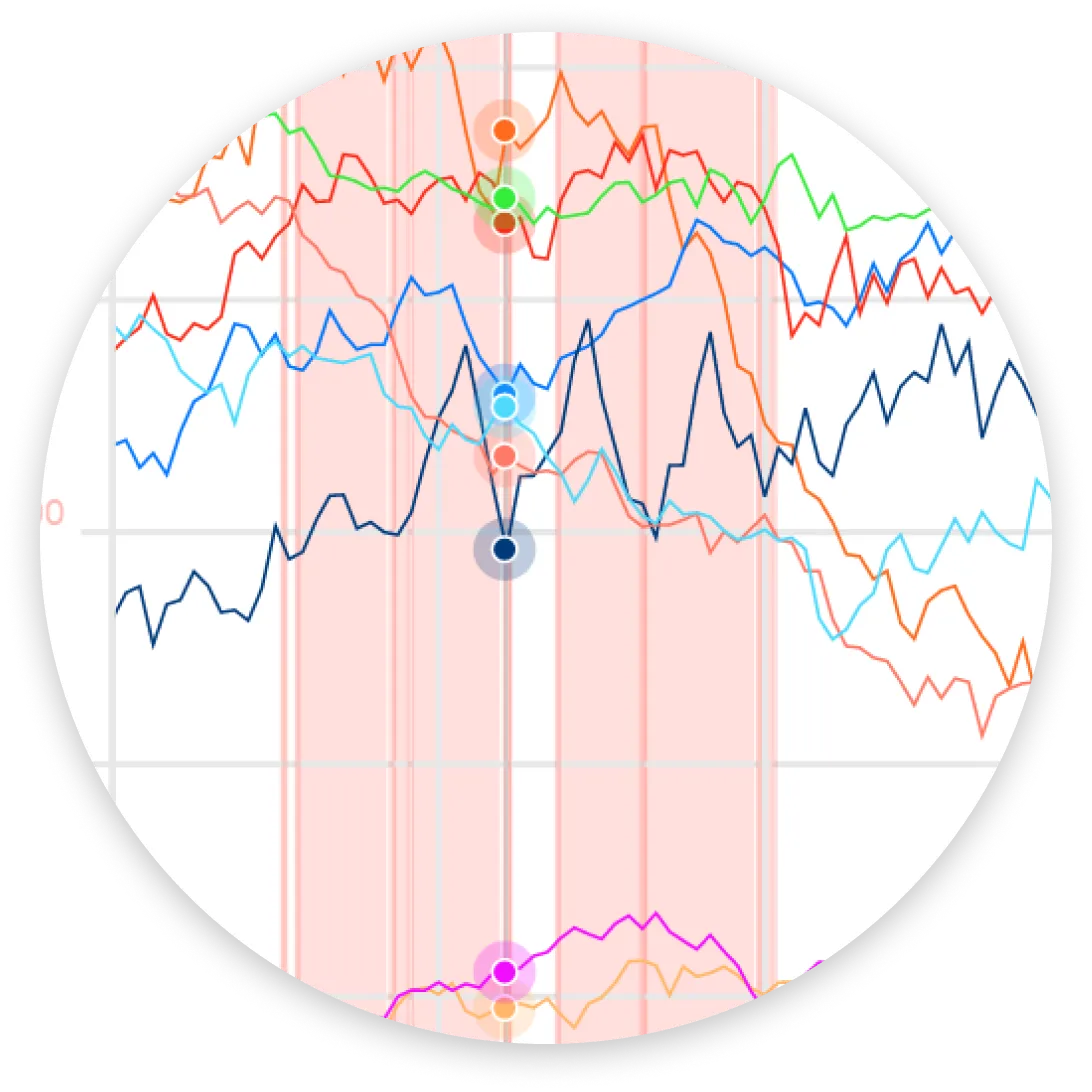

Rapid and effective interpretation of process, laboratory, and APC data at a glance. Intuitive root cause analysis.

See VPI in action

Analyse, detect missed opportunities and optimise

Thanks to advanced visual analytics, data conditioning and segmentation of operating conditions, VPI allows you to identify sub-optimal operating regions and missed opportunities, detect root causes and optimise process control.

On-site, off-site and personal installations

VPI Server can be installed on Windows, Linux and macOS. Public Cloud, Private Cloud, Bare Metal and local Desktop installations are allowed through a single universal installer.

Personal desktop

Private and public cloud

On-site

Platform and vendor independent - Aggregate multiple data sources

Aggregate and combine process, laboratory and off-line data from any major online data source (including classic OPC and UA), as well as from offline file-based sources.

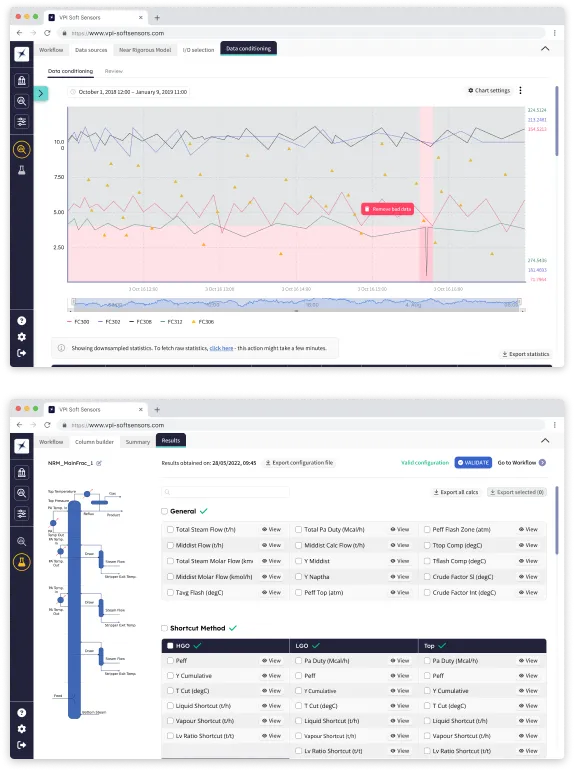

Available now: VPI Soft Sensors

A tool for quality estimation and column simulation to enhance workflows and boost performance.

Learn MoreHigh-quality, real-time predictors

Develop high-fidelity predictors of critical properties of your process, based on historical process data and past lab results.

Deploy the soft sensors online, integrate them with any existing APC application, including Shell PACE, AspenTech AspenIQ, and Honeywell Profit Sensor Pro, and optimise your control system.

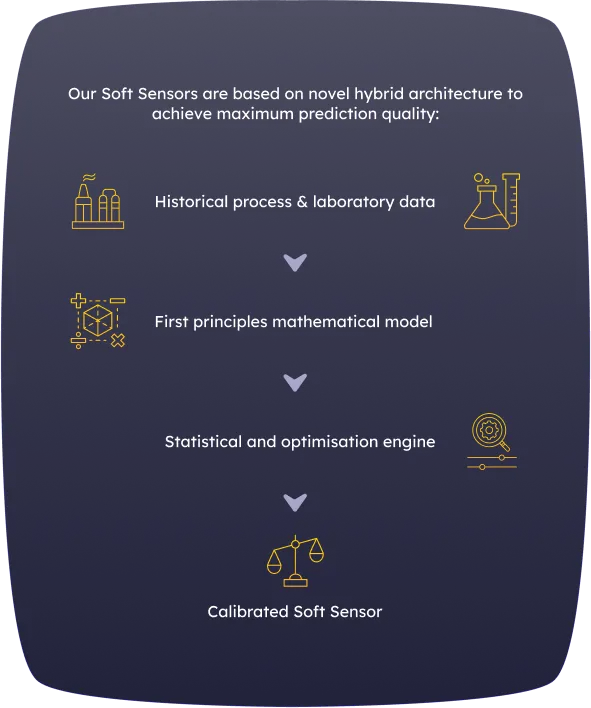

Novel hybrid model

VPI Soft Sensors are based on a novel hybrid architecture for predictive models, which combines:

Develop high-fidelity predictors of critical properties of your process, based on historical process data and past lab results.

Deploy the soft sensors online, integrate them with any existing APC application, including Shell PACE, AspenTech AspenIQ, and Honeywell Profit Sensor Pro, and optimise your control system.

The result are extremely accurate software predictors, robust to any operating condition, that can replace any physical online analysers.

Build and Calibrate models offline

The modelling process begins with an offline design stage:

VPI Soft Sensors is part VPI suite ,a powerful visual data analytics platform, providing data aggregation from multiple historians, data conditioning, processing, and visual intelligence.

A high-quality, first-principle based model of your distillation column, easily configurable visually via a web application add-on to your VPI platform.

Advanced machine learning and statistical models, combining the modelled state variables of the column to create accurate and robust predictors, using historical DCS and laboratory data from your plant.

Integrate Soft Sensors in real time

Completed soft sensors can be exported from the offline modelling suite and be integrated in an existing process control stack.

The soft sensors are combined with data available in real time to produce a high-frequency real time estimate with no delay. Thanks to the low computational effort, this type of application can run continuously, providing a constant monitoring of the unit operation.

Thanks to VPI Soft Sensors, you don't need to use costly online analysers to achieve highly optimised control performances.